Too much heat is the enemy of any CNC machinist. If you’re just starting out, working with materials that don’t transfer heat well can be a big challenge to overcome. Finding the balance between heat reduction and optimal material removal rates (MRR) can be a difficult task for even professionals to tackle.

In this article, we’ll look at a few of the most common methods for heat reduction in CNC milling.

Coolant For CNC Carving

Coolant, or cutting fluid, is a fantastic tool used to control the heat generated by your CNC system. There are several different ways coolants accomplish this and it largely depends on the type of material you’re milling.

Aluminum, for instance, can struggle to evacuate chips properly and recutting loose material can overheat your milling tools. Cutting fluid can help to clear them from the system. Coolants can also act as a lubricant, reducing the amount of friction—and therefore heat—generated.

Heat can also be transferred from the cutting tool and material to the coolant, preventing overheating of critical components. This is especially useful for materials that don’t transfer heat well such as titanium.

Climb Milling

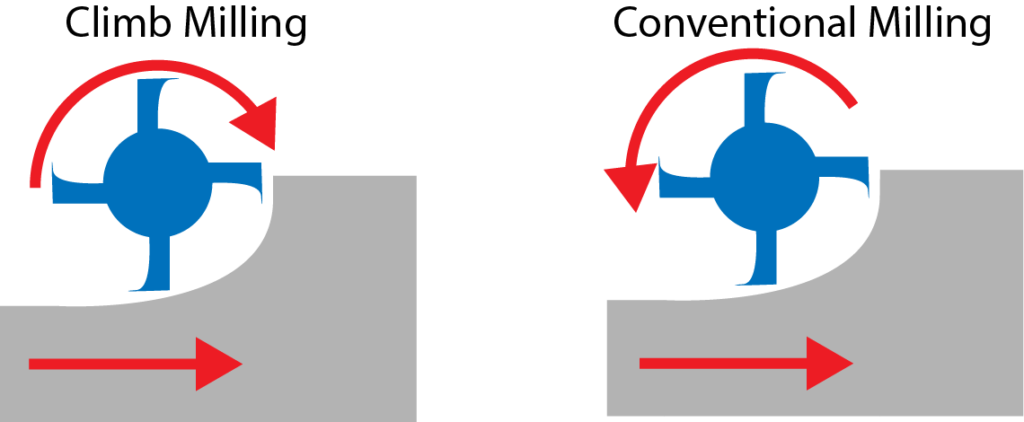

Another way to control heat generation is through the direction of your router’s rotation. In conventional milling, the spindle rotates against the direction of your feed. Alternatively, climb milling rotates with the direction of your feed.

In conventional milling, chip width begins at zero and increases in size as the cut progresses. Chips are carried upward and are recut, causing heat to diffuse into the material which can result in rubbing and work hardening.

On the other hand, climb milling chip width begins at the maximum and decreases at the end of the rotation. This method ensures that heat is transferred to the chips much more efficiently before they’re ejected from the system as opposed to conventional milling in which they’re often recut.

High-Efficiency Milling

High-efficiency milling is a technique that involves manipulating cut depths in order to optimize the material removal rate while decreasing the amount of heat produced.

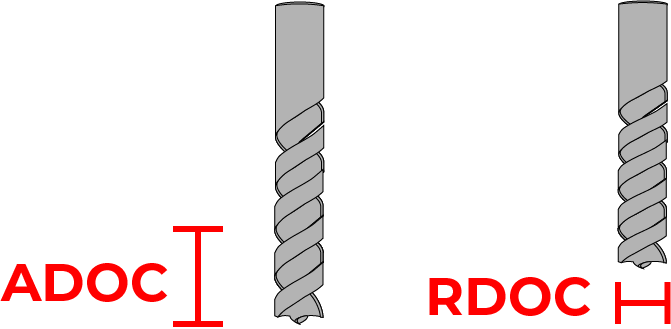

Experiment with two different measurements of radial contact: axial depth of cut (ADOC; how deep into the material the tool goes) and radial depth of cut (RDOC; the width of the bottom of the tool that contacts material).

A smaller RDOC and larger ADOC will reduce the amount of surface area is actually doing the cutting and therefore reduce the amount of heat generated.

For instance, plunging a tool into your material for a pocket will generate the most amount of heat because you’ve maximized the RDOC. The surface area of the tool will always be in contact with the piece, generating friction. Whereas a peripheral cut will only spend about half the time making contact with the material, producing much less friction and allowing the energy to dissipate outwards.

Heat generation is something to consider no matter what kind of material you’re milling. While some are more efficient at transferring heat than others, efficiency, tool longevity, and best practices are something every CNC machinist will need to take into consideration.

Whether you’re a beginner or a hardened professional, Inventables has the resources to help you realize goals and bring your ideas to life.